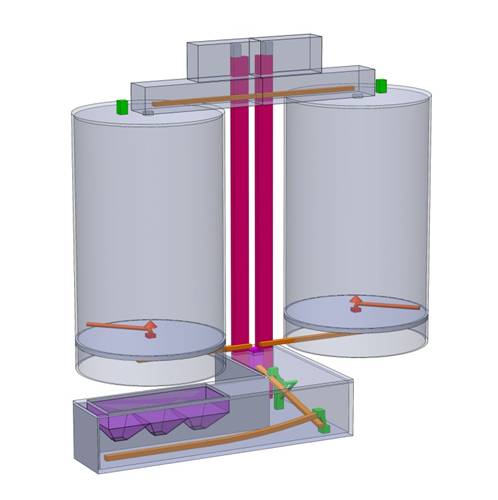

Technical Solution:

Silos will be designed for

you based on required capacity and your space possibilities. The silo as

such is made of concrete (for smaller volumes steel silos can also be

designed). Storage management as a system is always designed in close

cooperation with the client, taking into account properties of material

to be stored, layout possibilities, fire prevention standards and

regulations, process requirements, etc. Then we are able to deliver it

as a whole, including material unloading from road as well as railway

means of transport, conveying to the silos, discharge and transport from

the silos, connection to the existing technological and/or other

transport and control system, weighing, sampling, monitoring of material

characteristics, such as temperature, CO emissions, hydrocarbons,

smoke, and active elements of fixed fire-fighting equipment.

Basic Parameters:

Advantages of the solution:

• Material is discharged from the bottom of the silo – Fi-Fo (first in – first out)

• Online monitoring of material characteristics, such as temperature, CO emissions, hydrocarbons, smoke, etc.

• The system can be used for material re-loading in order to reach a problematic layer disposing only necessary volume

(the silo may be inactivated during that period)

•

There is no permanent operator inside the silo, no danger of

suffocation with CO and better monitoring of CO concentrations.

• Dustiness and noise can be solved successfully.

• Minimum ground-plan requirements in proportion to stored amount of material.